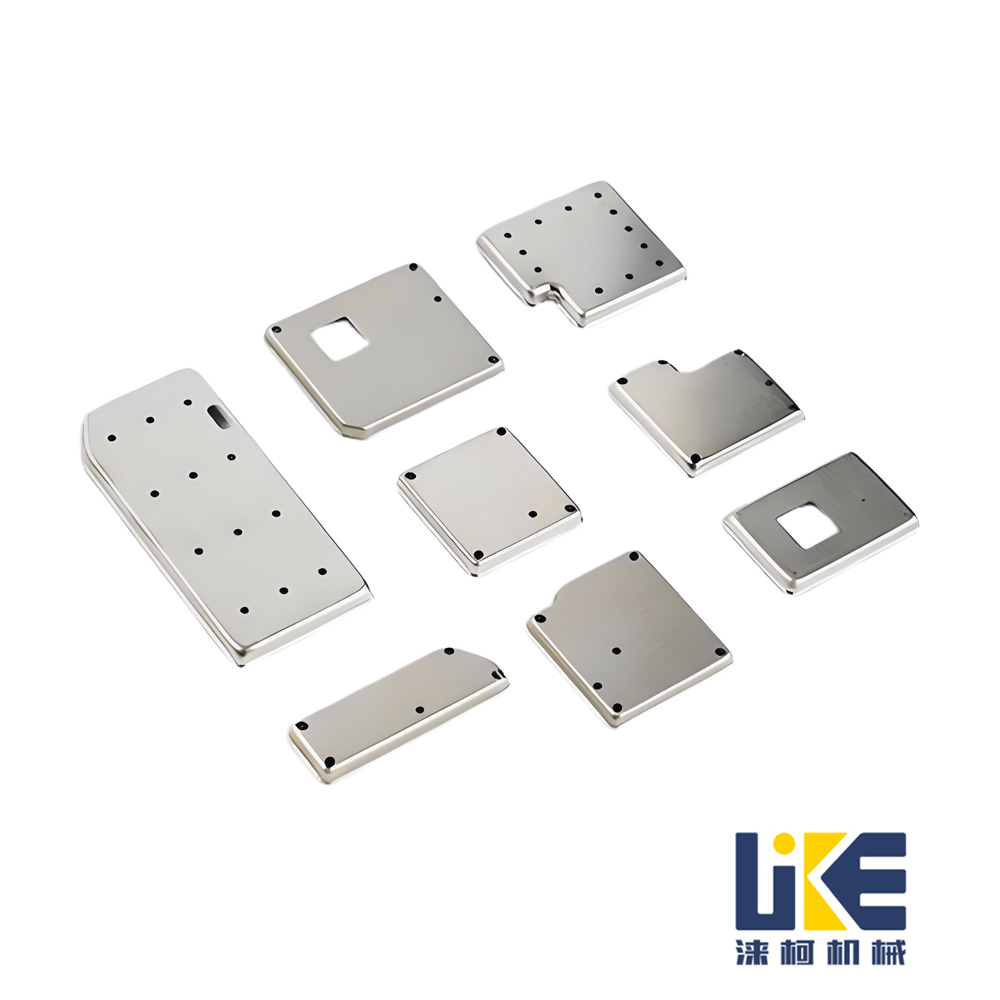

Electromagnetic (EM) shielding covers

These covers serve two primary and simultaneous purposes:

1. Protection from External Interference (Ingress Protection)

The cover prevents external electromagnetic signals from entering a device and disrupting its operation.Without this shielding, radio waves, electrical noise, or signals from nearby electronics could cause:

Data corruption: Errors in processing or storage.

Signal degradation: Static or noise in audio/video feeds.

System malfunction: Critical failures in sensitive equipment like medical devices or aircraft navigation.

2. Containment of Internal Emissions (Egress Protection)

The cover keeps the electromagnetic signals generated by the device from escaping.This is crucial for:

Security: Preventing "electronic eavesdropping" (e.g., shielding a keyboard so hackers cannot intercept keystrokes via radio waves).

Compatibility: Preventing the device from jamming or interfering with other nearby electronics (e.g., preventing a microwave from disrupting Wi-Fi).

How It Works

They are made of conductive or magnetic materials (such as copper, aluminum, steel, or conductive foams/paints). When electromagnetic waves hit the shield:

Reflection: Conductive materials reflect the waves away, similar to how a mirror reflects light.

Absorption: Magnetic materials absorb the energy of the wave and dissipate it as a small amount of heat.

Grounding: The shield captures the electric charge induced by the field and safely directs it to the ground, neutralizing the interference.

Common Applications

Consumer Electronics: Metal shields inside smartphones protect the processor from the antenna's signals.

Cables: The braided metal mesh layer in coaxial cables keeps the signal inside intact.

Medical: MRI rooms are lined with shielding (often copper) to prevent outside radio waves from ruining the scan images.

Military & Defense: Used to harden equipment against electromagnetic pulses (EMP) and prevent signal leakage that enemies could detect.