Subway and Metal stamping parts

Metal stamping parts, due to their high strength, high precision, and good consistency in mass production, have permeated every aspect of subway construction.

The following are the specific roles and application scenarios of metal stamping parts in subway construction:

1. Rail Fastening System - The cornerstone of safety

This is one of the most critical and widely used applications of stamped parts in subways. Track fasteners are used to secure steel rails to sleepers, preventing rail displacement.

Elastic Rail Clips:

Function: It utilizes the elastic deformation of metal to press down the steel rail, absorbing the vibration and impact from passing trains, and preventing the rail from flipping or longitudinally creeping.

Process: It typically utilizes high-quality spring steel, which undergoes heating, stamping and forming, and quenching treatment. It is a core component that ensures driving safety.

Gauge Baffles/Base Plates:

Function: Maintain a constant distance (gauge) between two rails and bear the pressure exerted by the rails.

Process: Stamping of thick steel plates, requiring extremely high dimensional accuracy and corrosion resistance.

2. Rolling Stock

Although modern subway car bodies are primarily constructed through welding aluminum alloy profiles, stamped parts play a dominant role in the internal structure and components of the vehicles.

Internal structural components:

Seat frame: Stainless steel or high-strength steel stamping parts, supporting the weight of passengers.

Handrail bracket/lifting ring: A metal connecting piece that connects the handrail rod to the vehicle body.

Door mechanism: Reinforcing ribs inside the door panel, and fixed brackets for the guide rail pulleys.

Electrical cabinet and control box:

Function: The outer shell of the traction inverter box and auxiliary power box located at the bottom of the vehicle.

Process: Sheet metal stamping and bending, requiring high sealing (waterproof and dustproof) and electromagnetic shielding performance.

Connection and shock absorption:

Bogie components: Certain brake pad backplates and shock absorber connecting seats are thick plate stamped parts.

3. Catenary & Power Supply

Subways rely on electricity to operate, and whether it's overhead contact systems or third-rail power supply, they are inseparable from stamped metal fittings.

OCS Fittings:

Dropper clamp: A small component connecting the messenger wire and the contact wire, typically a copper alloy stamped part, which is electrically conductive and corrosion-resistant.

Positioner clamp: Fixes the position of the contact wire to prevent it from swinging side to side.

Third Rail Brackets:

Function: If the subway adopts the third rail power supply (such as most lines of the Beijing subway), a large number of metal brackets are required to fix the live rail beside the roadbed.

Process: Stamping and bending of thick steel plates, requiring strong load-bearing and insulation support capabilities.

4. Tunnel M&E Installation

The subway tunnel is filled with various pipelines, and stamped parts serve as the "stewards" of these pipelines.

Cable Trays:

Function: To carry communication, signal, and power supply cables.

Process: Continuous punching and forming of galvanized sheets. Subway tunnels can extend for tens of kilometers, requiring a large amount of bridge frames.

Pipe Hangers & Clamps:

Function: To secure fire hoses and drainage pipes.

Process: It is commonly referred to as "pipe clamp", which is formed through stamping and can be installed quickly.

5. Station Decoration & Facilities

The appearance and structure of many metal facilities that passengers see in the station originate from stamping processes.

Aluminum Ceiling Panels:

Function: Decorative ceiling at the top of the subway station.

Process: Aluminum plate stamping and forming, with surface treatment options including perforation (for sound absorption) or spray painting. It features fire resistance, moisture resistance, and aesthetic appeal.

AFC Gates:

Function: The internal mechanical structure (connecting rod, rocker arm) and external stainless steel shell of the turnstile.

Process: Precision stamping ensures that the gate can open and close millions of times without malfunction.

Platform Screen Doors:

Function: Connection bracket inside the door frame and fixing plate for the drive mechanism.

6. Why is the construction of subways inseparable from stamped parts?

Fatigue resistance and safety: Subway trains operate for over ten hours a day, experiencing frequent vibrations. Stamped parts, especially those made of spring steel, possess excellent toughness and fatigue resistance, enabling them to withstand such high-frequency vibrations for extended periods without fracturing.

Massive demand and cost control: A single subway line requires millions of fasteners and hundreds of thousands of pipe clamps. The high efficiency of stamping process (tens of pieces per minute) is the only manufacturing method that can meet such massive demand at an economical cost.

Standardized construction: The high consistency of stamped parts ensures that workers can quickly carry out standardized installation in the dark and narrow tunnel environment, thereby shortening the construction period.

Summary

In subway construction, metal stamping parts serve as both "grips" (fastening rails) and "skeletons" (supporting cables and interior decoration), as well as "outerwear" (station decoration). Although they are mostly unobtrusive, they are the basic industrial components that ensure the safe, smooth, and efficient operation of subways.

Decorative items and metal stampings

Decorative items and metal stampings

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

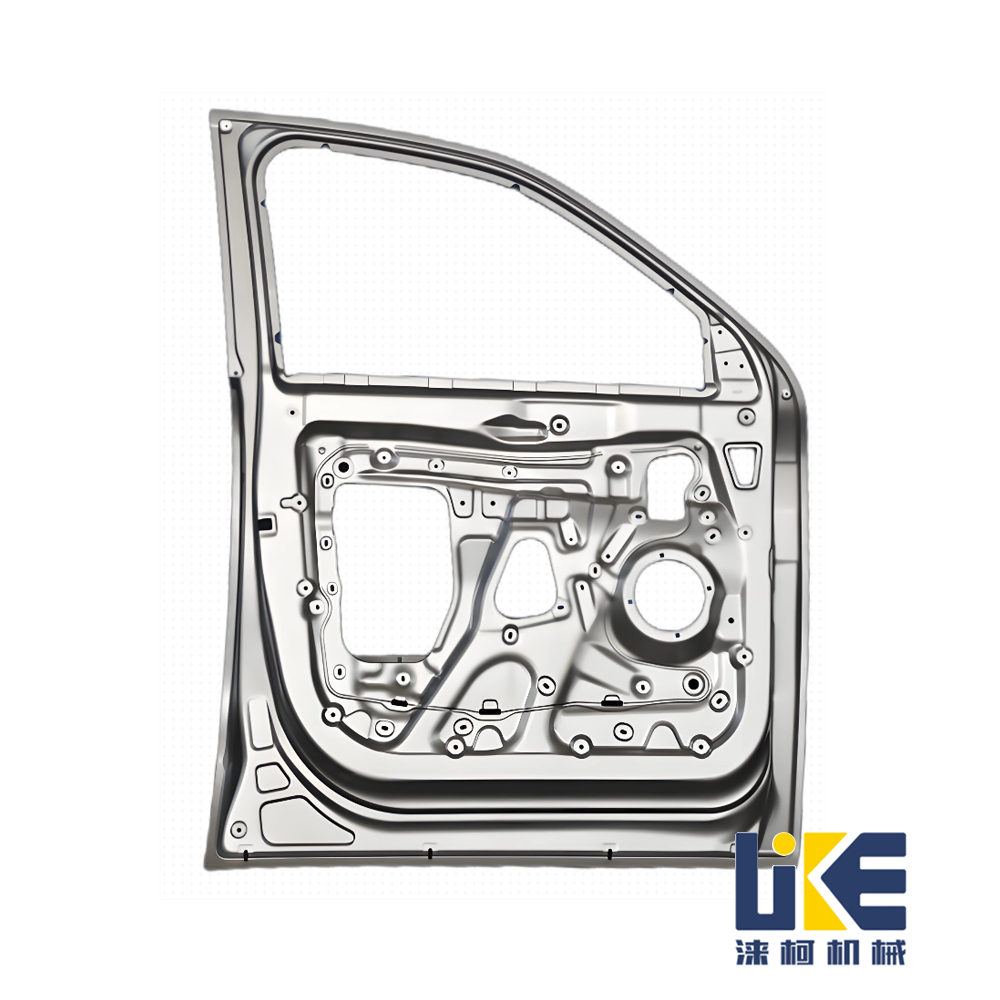

Automotive and metal stamping parts

Automotive and metal stamping parts