Air Conditioning System and metal stamping parts

The Hidden Backbone of HVAC: How Metal Stamping Parts Define Air Conditioning Efficiency and Durability

1. Heat Exchanger Fins: The "Lungs" of the Air Conditioner

High-Speed Precision: Using high-speed finned punch presses (operating at 300–500 strokes per minute), ultra-thinhydrophilic aluminum foil (0.09mm–0.15mm thick) is punched, flanged, and cut with incredible speed and accuracy.The Magic of Louvers: Stamping molds do more than just cut the foil. They create microscopiclouvers or bridge structures on every single fin.Why It Matters: These tiny stamped structures disturb the airflow, breaking the air boundary layer. This turbulence significantly increases the surface area and heat exchange efficiency. Without this precision stamping, air conditioners would be massive, inefficient energy hogs.

2. Outdoor Unit Casing & Chassis: The Sturdy "Armor"

Weather-Resistant Shell: Manufacturers usegalvanized steel plates (SECC/SGCC) that are cut, punched (for heat dissipation grilles), and bent into shape.Structural Integrity: You will often see complex lines and ridges on the casing. Thesestrengthening ribs are stamped into the metal not just for aesthetics, but to increase rigidity and reduce resonance noise caused by the fan.The Base Pan: This is the foundation that carries the heavy compressor and motor. Throughdeep drawing processes, thick steel plates are formed into a chassis. Crucially, stamped grooves guide rainwater away, preventing accumulation, corrosion, and freezing in winter.

3. Compressor Components: The "Heart" of the System

The Shell: The compressor casing is typically welded from twodeeply stretched semi-cylindrical steel shells . This stamped shape is essential for withstanding high internal pressure and ensuring a hermetic seal.Valve Plates: Inside the compressor, thevalve plates control the suction and discharge of refrigerant. These are ultra-precision stamped parts made from high-carbon steel. Because they open and close thousands of times per minute, they require exceptional flatness and fatigue life.

4. Motor Laminations: The Source of Power and Silence

Stator and Rotor Iron Cores: These are created usingsilicon steel sheets that are stamped and automatically stacked via high-speed progressive dies.Precision is Key: The accuracy of the stamping directly influences the motor's magnetic flux. High precision means higher energy efficiency (lower electricity bills) and reduced vibration (quieter operation). This is particularly vital for modernVariable Frequency (Inverter) air conditioners.

5. Structural Integrity and Safety

Wall Mounting Plate: The metal plate that secures the indoor unit to your wall is a masterpiece of functional stamping. Made from galvanized sheet metal, it features complex hooks and ribs designed to hold over 10kg of weight without deforming.Shock Absorption: Metal brackets connecting the compressor to the chassis are stamped at specific angles. When combined with rubber pads, these stamped parts act as a suspension system, absorbing vibration and preventing noise from traveling through the floor or wall.

Why the HVAC Industry Relies on Stamping

Energy Efficiency: The science of saving electricity starts with the stamping design of the fins. Optimized louver shapes mean faster heat exchange and less energy consumed.Durability: Plastic cannot survive the lifespan of an outdoor AC unit. Stamped metal, treated with galvanization and spraying, resists aging, temperature shocks, and rust for over a decade.Cost Control: With global demand for AC units in the billions, only stamping technology can produce complex parts like heat dissipation fins at the speed and low cost required to make air conditioning affordable for households worldwide.

Conclusion

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

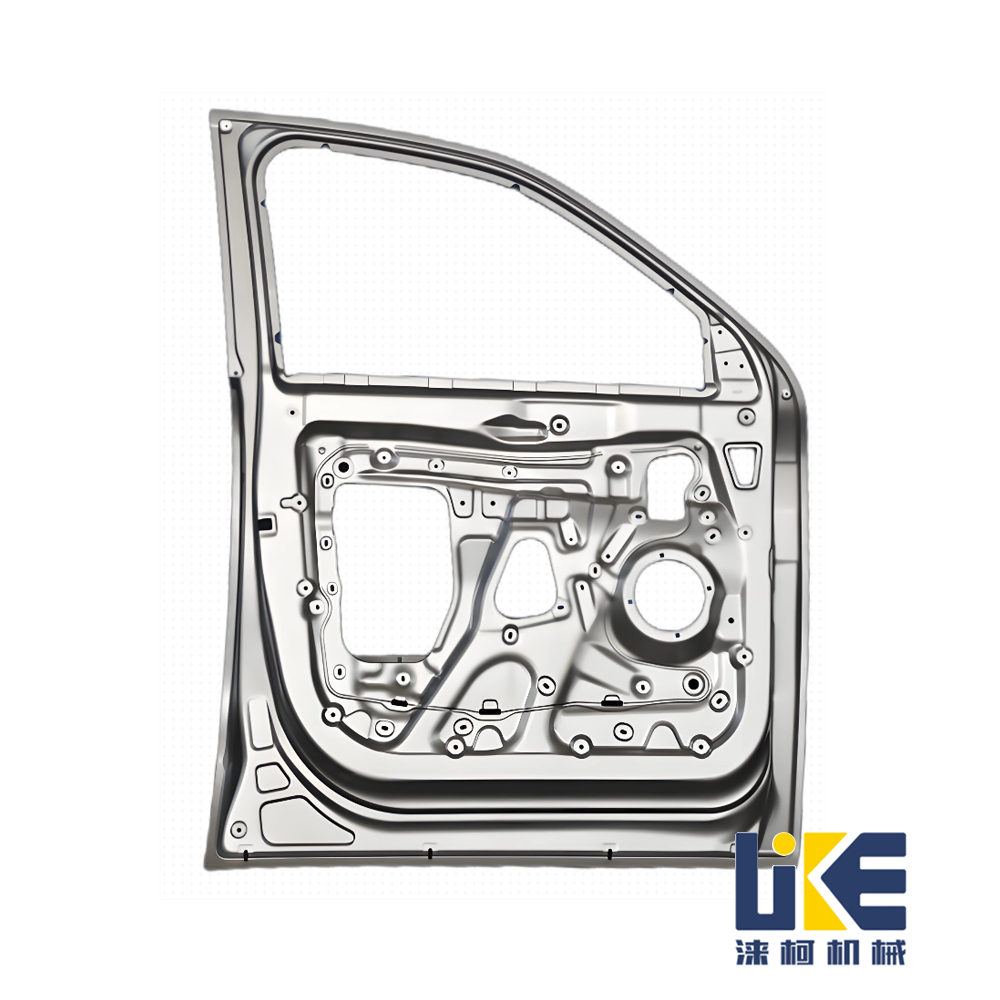

Automotive and metal stamping parts

Automotive and metal stamping parts

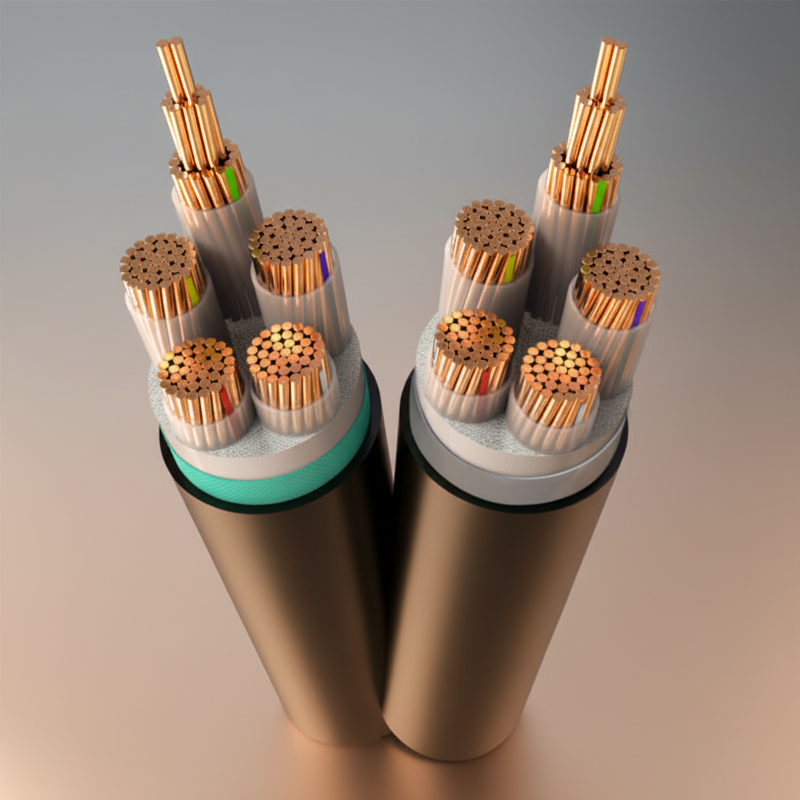

Cables and metal stamping parts

Cables and metal stamping parts