About Us

Decorative items and metal stampings

Views : 5

Update time : 2026-02-07 00:00:00

The Core Role of Metal Stamping in Decorative Item Manufacturing

Behind exquisite modern decorative items often lies a crucial manufacturing process—metal stamping. Whether it's the intricate patterns on vintage lamps or the gleaming metal clasps on fashionable bags, metal stamping plays an indispensable role.

It's not only the "skeleton" supporting the product but also the "skin" showcasing its design aesthetics. Below, we will analyze the specific role of metal stamping in decorative item manufacturing from four dimensions.

I. Form and Aesthetic Presentation: Giving Products a "High-Value Appearance"

This is the most direct role of stamping in decorative items. Compared to other metal processing methods, stamping can shape flat sheets into various complex three-dimensional forms with extremely high precision.

Fine Textures and Reliefs

Through embossing or coining processes, stamping dies can create delicate raised and recessed textures, brand logos, or antique effects on metal surfaces. For example, the embossed patterns on European-style metal box lids and commemorative badges are masterpieces of stamping technology.

One-Piece Molding of Artistic Forms

Many decorative items require streamlined or geometric shapes. Stamping can quickly create artistic forms such as flowers, leaves, and waves. Many wrought iron decorative paintings and metal floral and leaf fittings on lamps are actually formed in one stamping process using molds, resulting in smooth and natural lines.

Perfect Surface Finish Foundation

Stamped parts typically use materials such as brass, stainless steel, and aluminum alloys. These materials, after stamping, have a dense and smooth surface, making them ideal for subsequent electroplating (gold/silver/chrome), polishing, brushing, or anodizing, thus giving the decorative items a high-end metallic luster and texture.

II. Structural Support and Connection: The Invisible "Skeleton"

In many seemingly non-metallic decorative items (such as glass, crystal, and wooden crafts), stamped parts often serve an invisible supporting function, ensuring the product's durability.

Internal Skeleton Function: Many large decorative items (such as floor lamps and sculptures) require a lightweight yet sturdy frame to maintain their shape. Due to their "thin-walled, high-strength" characteristics, stamped parts are often used as the internal skeleton, supporting the entire product's outline.

Key Connectors: Various components of decorative items need to be assembled together, and stamped parts are often made into various brackets, clips, hinges, or bases. For example, the metal springs behind a picture frame or the metal butterfly clasp connecting a crystal ball to a crystal chandelier, though seemingly insignificant, determine the product's stability.

III. Cost Control and Mass Production Capability: Key to Commercialization

For commercial decorative item brands, choosing stamped parts is often a consideration of economic efficiency.

Alternative to Expensive Processes: Compared to casting (suitable for heavy parts, high cost, rough surface requiring secondary processing) or CNC machining (suitable for precision parts, but low efficiency and extremely high unit price), stamping can quickly produce uniformly shaped metal parts at a very low cost. This allows previously expensive metal decorative items to enter the market at a price acceptable to the general public.

High Material Utilization: Modern stamping processes (such as progressive dies), with optimized layout, can minimize the generation of waste from expensive metal materials (such as copper and 304 stainless steel), directly reducing raw material costs.

IV. Lightweight Advantages: Safety and Convenience

Reduced Hanging Burden: Stamped parts are formed from thin sheets, making them significantly lighter than cast parts of the same volume. This is crucial in hanging decorative items.

Application Scenarios: Bases for large crystal chandeliers, metal wall hangings, earrings, jewelry, etc. Lightweighting not only reduces the burden on the mounting wall or the wearer but also greatly improves safety.

Common Application Examples:

Lighting Fixtures: Lampshade housings, lamp bases, internal heat dissipation brackets.

Clothing and Bags: Metal buttons, belt buckles, decorative nameplates on bags, zipper pulls.

Home Furnishings: Curtain rod ends, furniture handles, metal picture frames, wall hangings.

Crafts and Gifts: Metal bookmarks, openwork pendants, commemorative coins.

Summary:

In summary, the role of metal stamping parts in the decorative industry can be summarized as: achieving complex metal aesthetic shapes at low cost while providing lightweight and robust structural support. For decorative manufacturers seeking a balance between design and cost-effectiveness, stamping is undoubtedly the best choice.

相关新闻

Decorative items and metal stampings

Decorative items and metal stampings

Feb 07,2026

The core role of metal stamping parts in the manufacturing of decorative items: from aesthetic design to structural support

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

Jan 26,2026

The main task of the Ventilation System is to introduce fresh air and expel stale air. In this system, metal stamping parts play the roles of "air guide", "connector" and "driver".

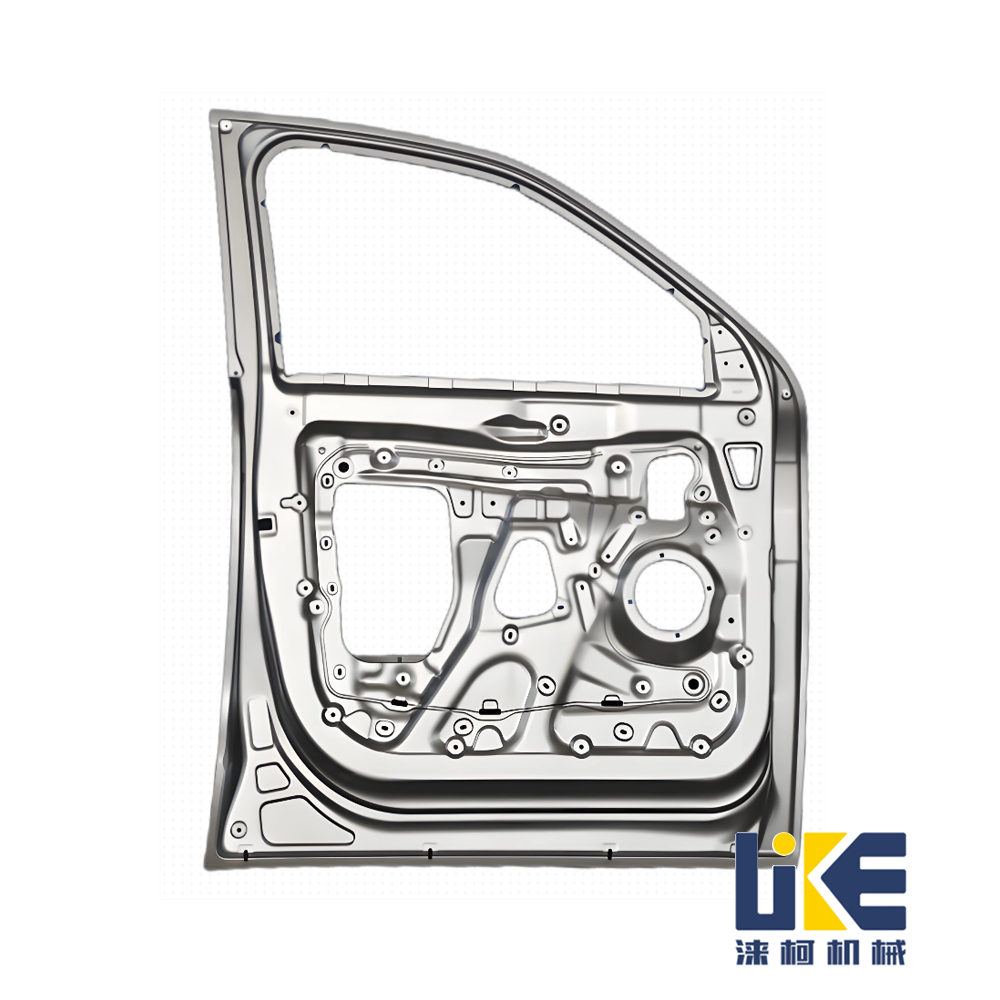

Automotive and metal stamping parts

Automotive and metal stamping parts

Jan 25,2026

The automotive industry is the most mature, largest, and technologically advanced field for the application of metal stamping parts. It can be said that without stamping technology, there would be no large-scale assembly line production in the modern automotive industry.