Ventilation systems and metal stamping parts

The requirements for ventilation system components mainly focus on low air resistance (smooth), low noise, good sealing, and easy installation. The metal stamping process, with its ability to process streamlined surfaces and high-precision mating parts, perfectly meets these requirements.

The following are the specific functions and application scenarios of metal stamping parts in ventilation systems:

1. Air Vents&Diffusers - the "outlet" of airflow

This is the most common ventilation component we see on ceilings or walls.

Louvers/Grilles:

Function: To guide the direction of airflow (upward, downward, or horizontal).

Craftsmanship: Each blade is formed through a stamping die with a specific curvature to conform to aerodynamics and reduce wind noise.

Frame: The outer frame of the air vent is usually stamped and bent from aluminum alloy or steel plate to ensure a flat and beautiful appearance.

Round Diffusers:

Function: Allow air to spread evenly in all directions.

Process: Typical Spinning or Deep Drawing stamping process. Stretch the flat plate into multiple concentric conical shapes.

Jet Nozzles:

Used for remote air supply in tall spaces such as airports and sports venues, its spherical structure is usually made of aluminum plates that are stretched and stamped.

2. Duck Accessories - the "joints" of the system

Ventilation ducts are usually rectangular or circular, and their connection and fixation cannot be separated from stamped parts.

Flange Corners/Cleats:

Function: A metal corner code must be inserted at the four corners of the rectangular air duct (common flange air duct) to connect and reinforce it.

Craftsmanship: This is the most widely used stamping part in the ventilation industry. High speed stamping of thick galvanized sheet requires extremely high dimensional accuracy to ensure smooth insertion and sealing.

Duct clamps:

Function: Connect circular air ducts.

Process: Steel strip stamping with locking mechanism.

Hangers & Brackets:

Function: Hang heavy air ducts under the ceiling.

Specifically: C-shaped steel buckle, screw hanger, shock-absorbing hook (stamped part with rubber in the middle), used to prevent the vibration of the air duct from being transmitted to the building structure.

3. Fan&Blower Components - the "power source" of the system

The fan is the heart of the ventilation system, and the stamping parts determine the efficiency and noise of the fan.

Impellers/Blades:

Function: Rotate and push air.

Craftsmanship: Whether it is the fan blades of axial flow fans or the multi wing blades of centrifugal fans, they are mostly metal stamped parts.

Key: The stamping die ensures that the surface shape and weight of each blade are completely consistent, which is crucial for the dynamic balance of the fan. If the weight of the blades is uneven, the wind turbine will vibrate violently.

Scroll Housing:

Function: The outer shell of the centrifugal fan collects and guides the airflow.

Process: Side panels are usually stamped and cut from galvanized sheets, and connected by biting or welding.

Inlet Cone:

Function: Guide air smoothly into the fan and reduce turbulence.

Process: The horn shape is produced by deep drawing and stamping.

4. Air volume control valve and Dampers - the "switch" of the system

In ventilation ducts, it is necessary to control the air volume or automatically cut off the airflow in case of a fire.

Damper Blades:

Function: Block or pass through airflow.

Process: Stamped metal plates, usually with reinforcing ribs to prevent deformation under high wind pressure.

Execution mechanism accessories:

Handle: A stamped handle for manually adjusting the air valve, usually with a dial.

Linkage: A metal connecting rod that connects multiple valve plates to rotate synchronously.

Temperature sensor fuse:

The core component of a fire damper. When the temperature reaches 70 ℃ or 280 ℃, this metal plate (or melting alloy mechanism) will act and the spring will close the valve.

5. Filtration

Filter frame: Primary and medium filters typically use stamped and bent metal frames or stamped mesh protectors to support the filter material.

Why does the ventilation system rely on stamped parts?

Aerodynamics:

The air flow is most afraid of sharp edges and burrs (which can cause whistling and resistance). Stamping technology (especially stretching) can create rounded and streamlined metal surfaces (such as air intakes and diffusers), making air flow smoother and reducing noise.

Sealing:

If the size error of the corner code and flange at the connection of the air duct is large, it will leak air and cause energy waste. Precision stamping ensures a tight fit of the connecting parts.

Lightweight and Strength:

Ventilation ducts are usually hung above the head, and the lighter the requirement, the better. Stamping technology can significantly improve the rigidity of parts and prevent the vibration and roar of air ducts by pressing reinforcing ribs (Ribs) on thin plates without increasing thickness and weight.

summary

The role of metal stamping parts in ventilation systems is to:

Smooth the wind: reduce resistance and noise through streamlined impellers and air vents;

Stabilize the wind: Ensure tight and secure pipeline connections through sturdy brackets and hangers;

Control the wind: Through precise air valve components, precise adjustment and safe blocking of airflow are achieved.

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

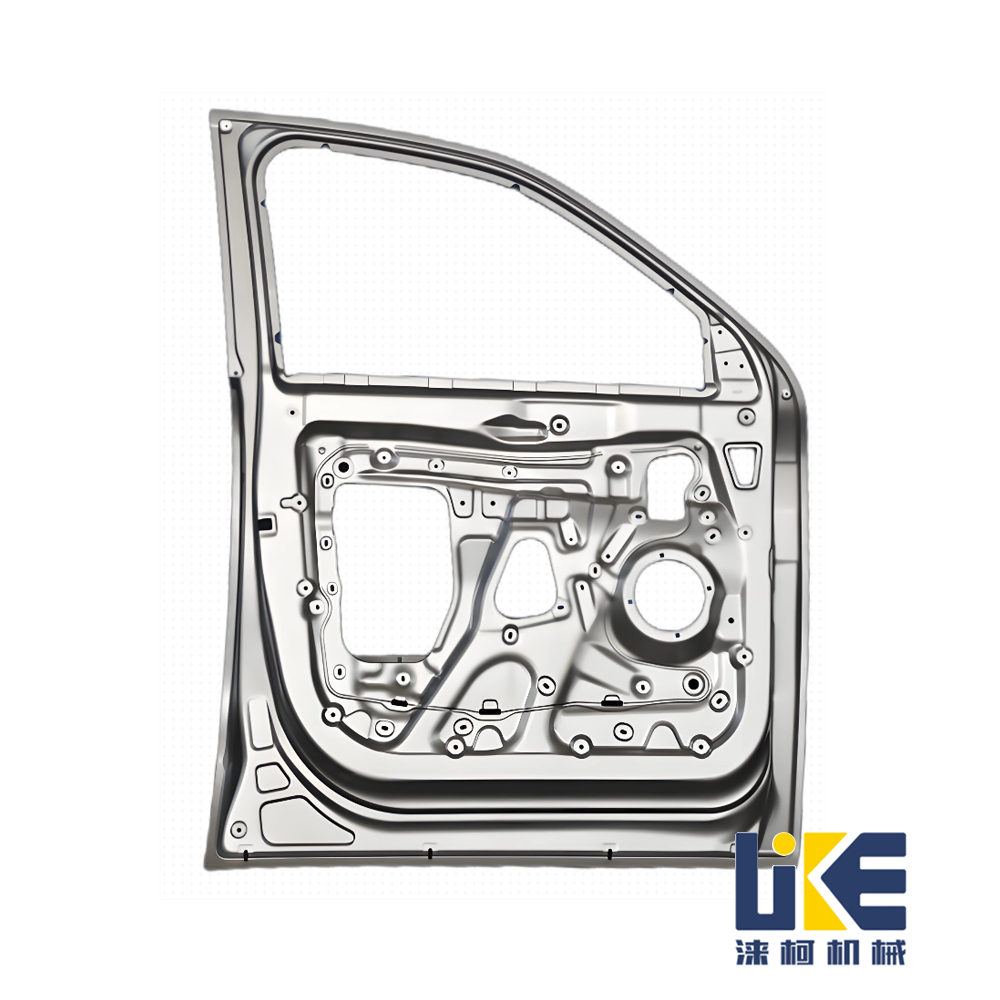

Automotive and metal stamping parts

Automotive and metal stamping parts

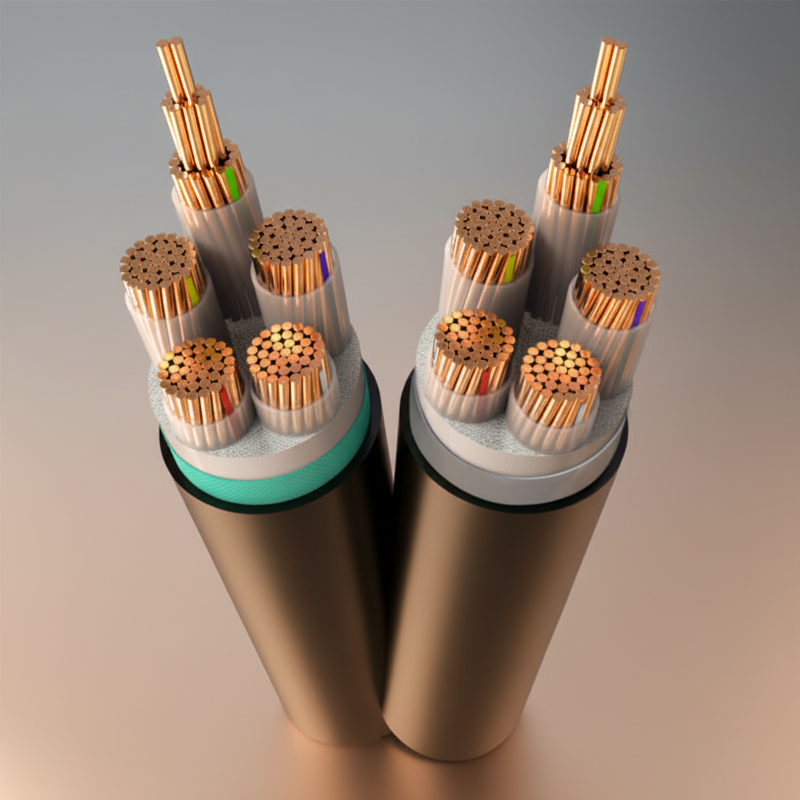

Cables and metal stamping parts

Cables and metal stamping parts

Numerical control equipment and metal stamping parts

Numerical control equipment and metal stamping parts