High-Speed Rail / CRH and Metal stamping parts

Metal stamping parts in the high-speed railway system not only serve as connecting elements but also play a crucial role in ensuring the safety and comfort of high-speed operation.

The following are the specific roles and core application scenarios of metal stamping parts in the field of high-speed rail:

1. Rail Fastening System - The "Stabilizing Magic Needle" for High-Speed Operation

This is the most core and highly technical application of stamped parts in the railway industry. With the speed of bullet trains reaching over 300km/h, steel rails are subjected to tremendous impacts and high-frequency vibrations.

High-strength elastic rail clips:

Function: It firmly "presses" the rail onto the sleeper, while utilizing the elastic deformation of metal to absorb the severe vibrations caused by high-speed trains passing by, thus preventing the rail from loosening or breaking.

Process: It utilizes special spring steel, which undergoes precision stamping, hot bending, and rigorous heat treatment. It must ensure that no fatigue fracture occurs under hundreds of millions of vibrations.

Base Plates:

Function: Disperse pressure and protect the sleeper.

Process: Thick plate stamping, requiring extremely high flatness.

2. Lightweight Body Structure

In order to increase speed and save energy, multiple unit trains must pursue "lightweight" to the extreme. Stamped parts provide the best weight reduction solution without sacrificing strength.

Aluminum alloy/stainless steel structural components:

Function: Although the main frame of the vehicle body is mostly made of aluminum profiles, the internal reinforcing ribs, connecting brackets, and equipment mounting brackets are largely made of high-strength aluminum alloy or stainless steel stamped parts.

Specifically: the fixed bracket for the roof air conditioning unit and the support structure for the underbody skirt.

Honeycomb Panels:

Function: Used for partitions, floors, and ceilings inside the vehicle cabin.

Craftsmanship: It consists of two extremely thin metal panels (stamped and formed) with a honeycomb core sandwiched in between, making it both lightweight and soundproof.

3. Bogie Components - The "legs" of the train

The bogie is the most crucial running component of a high-speed train, directly affecting safety.

Brake Pad Backplate:

Function: During the braking of a high-speed train, extremely high temperatures and substantial shear forces are generated. The brake friction material must be attached to a high-strength steel plate, which is a thick stamped part.

Requirements: Extremely high flatness and shear strength.

Dust cover and sealing component:

Function: Protect the bearing and gearbox from sand, rain, and snow intrusion.

Process: Deep drawing and stamping process.

Sensor bracket:

Function: Fixing speed sensors and temperature sensors to monitor the health status of the train in real time.

4. Pantograph & Catenary —— Energy Source

The bullet train obtains power from the overhead contact system via its pantograph.

Pantograph carbon strip bracket:

Function: To support the carbon sliding plate that comes into direct contact with the wire.

Process: Precision stamping of aluminum alloy, requiring extreme lightness (to reduce impact on the contact network) and good aerodynamic performance (to reduce wind resistance and noise).

OCS dropper and clamp fittings:

Function: A metal clamp used to suspend the contact wire from the messenger wire along the railway.

Process: Stamping with copper alloy or copper-aluminum composite material, which requires conductivity, corrosion resistance, and the ability to withstand high-frequency micro-wind vibration.

5. Interior & Facilities

To provide a comfortable riding experience, the interior facilities of the carriage make extensive use of precision stamped parts.

Seat Frames:

Function: The seats for bullet trains must be capable of rotating and tilting, and they must be lightweight. The core components inside, including the turntable mechanism, backrest adjustment mechanism, and base connectors, are all high-strength steel stamped parts.

Rotating mechanism: It refers to the base device that allows the entire row of second-class seats to rotate and turn around. The core of this mechanism is formed through stamping.

Luggage rack assembly:

Function: To bear heavy loads.

Process: Combination of aluminum alloy stamping and extrusion.

Air conditioning outlet:

Function: Regulate the direction of airflow. It is usually stamped from thin aluminum sheets.

6. Electrical Control

Connector Terminals: The tens of thousands of wire harness connections inside electric vehicles rely on high-reliability gold-plated/silver-plated copper stamped terminals to ensure zero signal transmission failures.

Shielding box: Protects the Train Control System (TCS) from electromagnetic interference.

7. Why is the high-speed railway heavily reliant on stamped parts?

Weight Reduction: For every 1 ton reduction in the weight of a train, both energy consumption and braking distance will see significant improvements. Stamping process, capable of processing thin-walled high-strength materials, is the preferred choice for achieving lightweight design.

Consistency: Railway maintenance requires extremely high standardization. The parts produced by stamping molds (such as track fasteners) are exactly the same in size, whether they are the first or the one millionth, which is crucial for the maintenance of railway lines that stretch for thousands of kilometers.

Vibration Resistance: Stamped parts (especially those made of heat-treated spring steel) exhibit excellent toughness. Unlike castings, they are not brittle, and unlike weldments, they are less prone to cracking at the weld seam, making them highly suitable for high-vibration environments such as high-speed trains.

summary

In the field of high-speed rail, the role of metal stamping parts can be summarized as "ensuring lightness externally and safety internally".

From a macro perspective, they help trains run faster through lightweight design;

At the micro level, they (such as spring clips and brake steel backs) firmly engage under extreme stress, ensuring that trains run more stably and can stop safely.

Decorative items and metal stampings

Decorative items and metal stampings

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

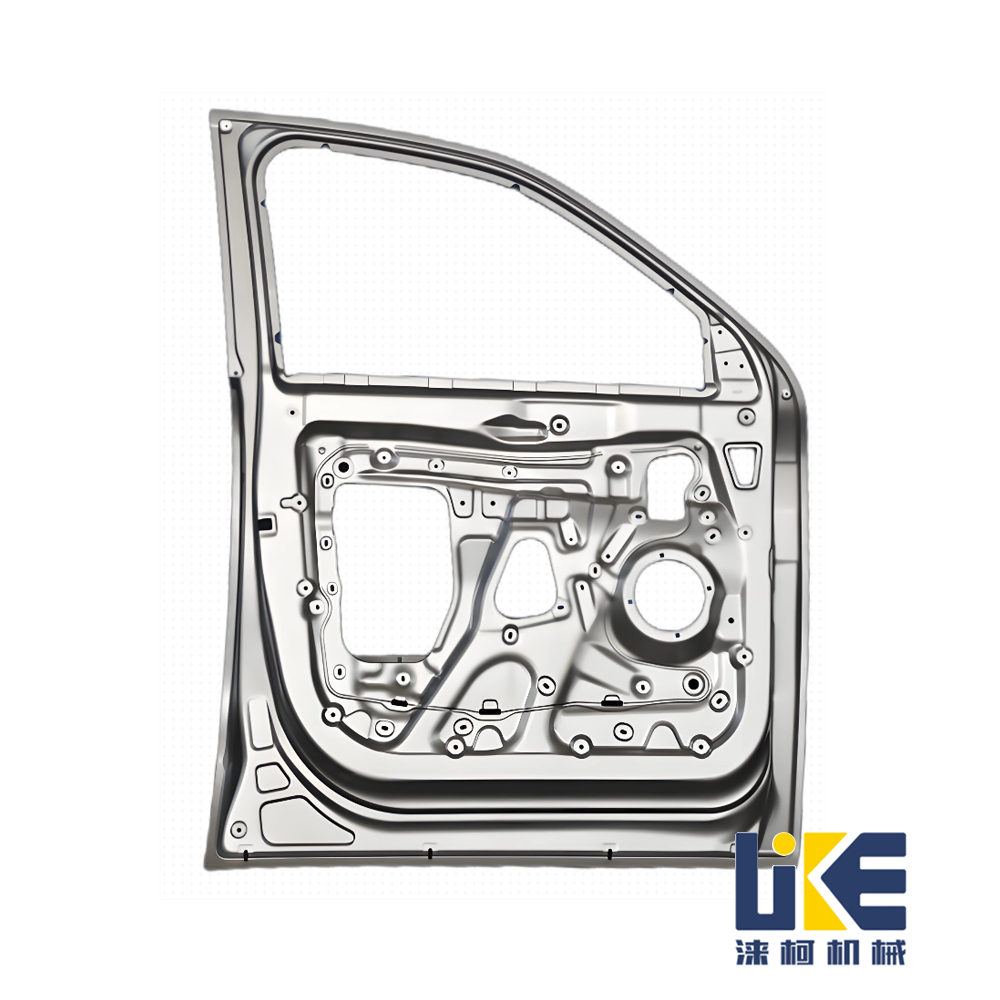

Automotive and metal stamping parts

Automotive and metal stamping parts