Household appliances and metal stamping parts

In the home appliance industry, the stamping process mainly addresses three major issues: aesthetic appearance, structural support, and cost-effective mass production.

The following are the specific roles and application scenarios of metal stamping parts in the home appliance industry:

1. Appearance & Enclosures —— The "appearance value" of the product

Home appliances are placed in a domestic environment, thus the requirements for the surface quality, flatness, and design of the shell stamping parts are extremely high.

Function: Protect internal components, provide an aesthetically pleasing design, and protect against dust, moisture, and radiation.

Specific products:

Refrigerator door and side panels: PCM/VCM (pre-coated steel sheet) is typically used, which is formed through bending and shallow drawing. The surface is required to be free of scratches and wavy patterns.

Washing machine/drying machine shell: stamped and sprayed with galvanized sheet, requiring strong rust resistance.

Microwave oven/oven casing: Stainless steel or cold-rolled sheet stamping, with the need to prevent microwave leakage.

Air conditioning outdoor unit casing: It needs to withstand exposure to wind and sun, and typically features a complex design of reinforced ribs to prevent resonance noise.

2. Internal Structure & Chassis —— The "skeleton" of the product

Users usually cannot see these components, but they determine the robustness and lifespan of household appliances.

Function: Support core components such as motors, compressors, and circuit boards, and withstand vibration and weight.

Specific products:

Backplane: Especially for LED/OLED TVs, the backplane is typically made of stamped galvanized or aluminum plates, which serve both as a heat sink and as a support for the large screen.

Washing machine base: It can withstand the huge centrifugal force and vibration during high-speed spinning.

Air conditioning wall-mounted back plate: This refers to the metal plate that is nailed to the wall to hang an air conditioner, and it must possess extremely high strength.

Compressor base: Used to secure the compressor of a refrigerator or air conditioner.

3. Heat exchangers - the "lungs" of air conditioners and refrigerators

This is a unique and highly technical stamping application in the home appliance industry.

Fin Stock:

Function: Significantly increase the heat dissipation area for heat exchange.

Process: A high-speed punch press is used to punch complex louver hole patterns into extremely thin aluminum foil (approximately 0.1mm thick), which is then threaded onto a copper tube. This is crucial for the efficiency of air conditioning and heating systems.

Heat sink: Aluminum heat sink for the mainboard of TV and internal chips of set-top box.

4. Motor Components —— The "heart" of home appliances

All home appliances that can rotate (fans, washing machines, air conditioners, vacuum cleaners, blenders) have motors inside, and motors cannot do without stamping.

Stator & Rotor Laminations:

Function: Generates a magnetic field to drive the motor to rotate.

Process: It is made of silicon steel sheets through high-speed progressive die stamping and automatic lamination. The stamping accuracy directly affects the energy efficiency ratio (energy saving) and noise level (quietness performance) of the motor.

5. Functional Containers

Rice cooker inner pot:

Process: Deep Drawing process. A round aluminum plate or stainless steel plate is stretched into a deep barrel shape.

Function: To hold food and conduct heat.

Washing machine inner drum:

Process: After the stainless steel plate is rolled into a circle and welded, thousands of dehydration holes and raised massage ribs are punched out on the cylinder wall through a stamping mold.

Microwave oven cavity:

Function: It is necessary to form a closed Faraday cage to prevent microwave leakage from harming people. The precision of the stamping and fitting of the door hook and door frame is extremely high.

6. Small Hardware

Plug and socket spring: Phosphor copper stamped parts ensure good conductive contact.

Hinges: The opening and closing mechanism of refrigerator and oven doors, which needs to withstand tens of thousands of cycles of opening and closing without wear and tear.

7. Why is the home appliance industry so heavily reliant on stamping?

Cost & Efficiency: Home appliances are typical large-scale assembly line products. If a washing machine's shell is processed using CNC, the cost would be astronomical; whereas using a stamping mold, a shell can be produced in just a few seconds at a very low cost.

Aesthetics: Modern home appliances pursue streamlined design. Stamping processes, especially drawing and shaping, can easily achieve complex curved surface designs, meeting the requirements of industrial design.

Material utilization rate: Compared to cutting processes, stamping can minimize material waste, which is crucial for the home appliance industry, which is extremely cost-sensitive.

Lightweight: Compared to castings, stamped parts can achieve the same strength with thinner materials, facilitating the transportation and handling of household appliances.

summary

In the home appliance industry, metal stamping is the primary method for transforming raw materials (steel plates/aluminum plates) into final product forms.

It makes home appliances look good (with exquisite shells);

It makes household appliances durable (with a sturdy frame);

It makes household appliances efficient (with precise motor blades and cooling fins);

Most importantly, it makes home appliances affordable and accessible to millions of households at a low price.

Decorative items and metal stampings

Decorative items and metal stampings

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

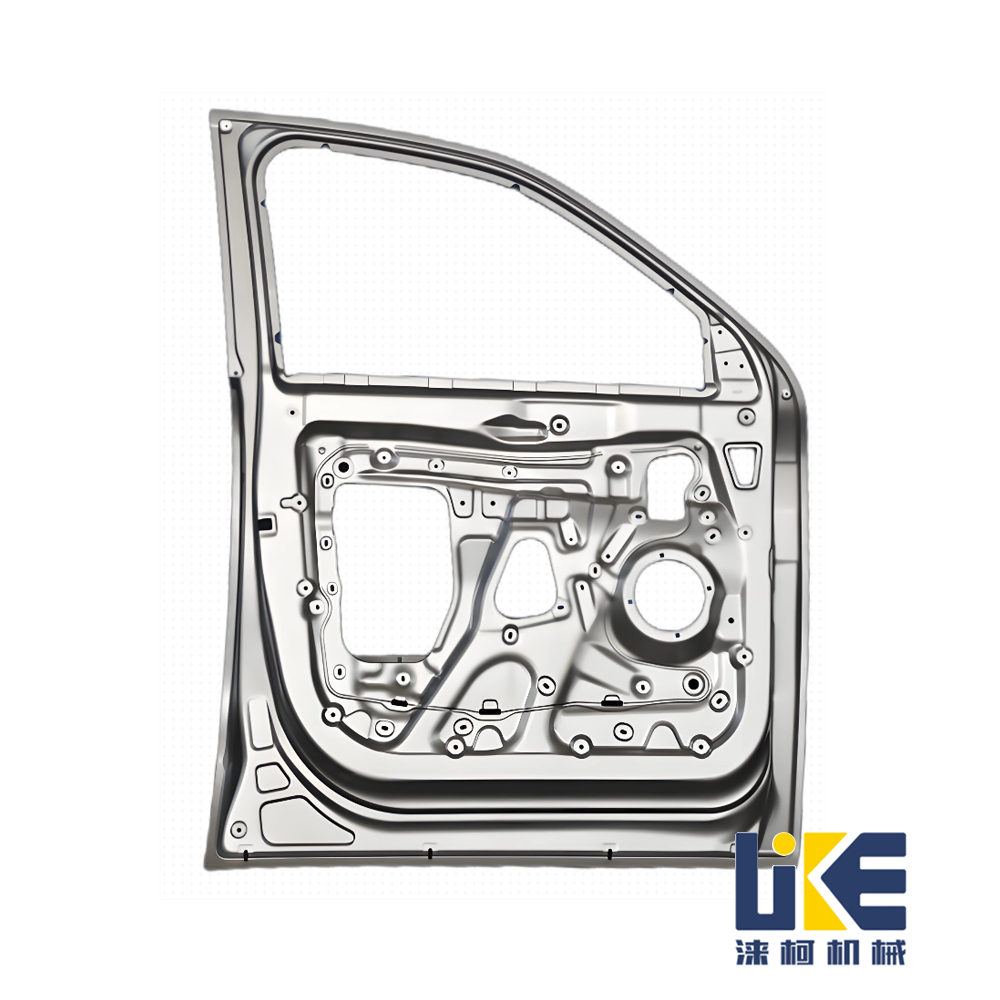

Automotive and metal stamping parts

Automotive and metal stamping parts