Office supplies and metal stamping parts

The following are the specific roles of metal stamping parts in the office supplies industry:

1. Desktop Tools - the most classic application

This is the most intuitive presence of stamped parts in the office field. These tools require frequent application of force, and plastic cannot meet the strength requirements. Additionally, the cost of cutting and machining is too high, making stamping the only viable option.

Staplers:

Function: The entire stapler, including its internal mechanism, nail pusher, base, and upper cover, is almost entirely stamped from nickel-plated or painted steel plates.

Key point: The stamped parts must ensure extremely high fit accuracy, otherwise the "stake sticking" phenomenon may occur.

Hole Punches:

Function: Lever structure for pressing down, knife edge guide plate at the bottom, and bottom cover for collecting paper scraps.

Key point: The stamped parts near the cutting edge need to undergo heat treatment to ensure hardness, so as to cut through paper cleanly.

Binder Clips:

Function: The black triangular clamp body is made of spring steel through stamping, bending, and heat treatment.

Key point: Utilize the resilience of metal after stamping to grip the paper. This is a classic example of the "application of elasticity" in stamping processes.

Staple Removers:

Function: Two metal teeth that mesh together are formed through stamping and connected using rivets.

2. Writing Instruments

Although the penholder is mostly made of plastic or copper tube, the key small parts cannot be separated from precision stamping.

Pen Clips:

Function: Do not put it in your pocket or notebook.

Process: Stamping and forming with stainless steel or copper sheets. The pen clip of high-end pens has extremely high requirements for the appearance (no burrs) and elasticity of the stamping process. It needs to be able to grip tightly without breaking.

Pressing structure:

Function: The ratchet mechanism and spring retainer inside a ballpoint pen, often made of micro stamped parts, determine whether the "click" sound when pressing is crisp or not.

3. Office Furniture & Storage

The durability of the office environment primarily relies on metal components.

Filing Cabinets:

Drawer Slides: The core of a smoothly sliding drawer. The slide rail is made from steel strip through **continuous roll forming (Roll Forming, a broad sense of stamping)** or long mold stamping.

Hanging rack: A metal strip used to hang folders in a drawer.

Office Chairs:

Mechanism: The black, heavy metal tray beneath the chair seat is responsible for lifting, lowering, and reclining. It is a thick plate stamping part that must withstand the weight of an adult and repeated shaking, involving safety issues.

Grid storage series:

Function: Pen holder, document tray.

Process: Perforated Metal process. The entire steel plate is punched out with densely packed holes and then stretched into shape.

4. Office Automation - OA

Printers, photocopiers, and shredders are filled with complex mechanical movements inside.

Printers/Copiers:

Paper Path: The metal guide plate that guides the paper transmission must have an extremely smooth surface (polished or plated after stamping) to prevent paper jams.

Ink cartridge/toner cartridge contact: conductive metal spring.

Frame: A galvanized sheet metal frame that supports the heavy scanning components and print engine.

Shredders:

Blade spacer: A metal spacer that separates and secures rotating blades.

5. Why is stamping indispensable in the office supplies industry?

Cost Efficiency:

The price of a paperclip may be just a few cents. Only a stamping die can produce hundreds of them per minute, driving down the cost per unit to a negligible level.

Elasticity:

Office supplies often involve "clamping" functions (pen clips, ticket holders, stapler springs). Spring steel processed by stamping has unparalleled fatigue resistance compared to plastic, and will not loosen due to prolonged clamping.

Wear resistance and strength:

Staplers and punchers need to withstand substantial mechanical forces, and plastic parts are prone to breaking, whereas metal stamped parts are durable and long-lasting.

summary

In the office supplies industry, the role of metal stamping parts is to "show craftsmanship in the finer details".

It embodies the powerful "one-grip" of a paperclip, the delicate "one-click" of a ballpoint pen, and the crisp "click" sound of a stapler. The stamping process ensures that these frequently used tools are both affordable and durable.

Decorative items and metal stampings

Decorative items and metal stampings

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

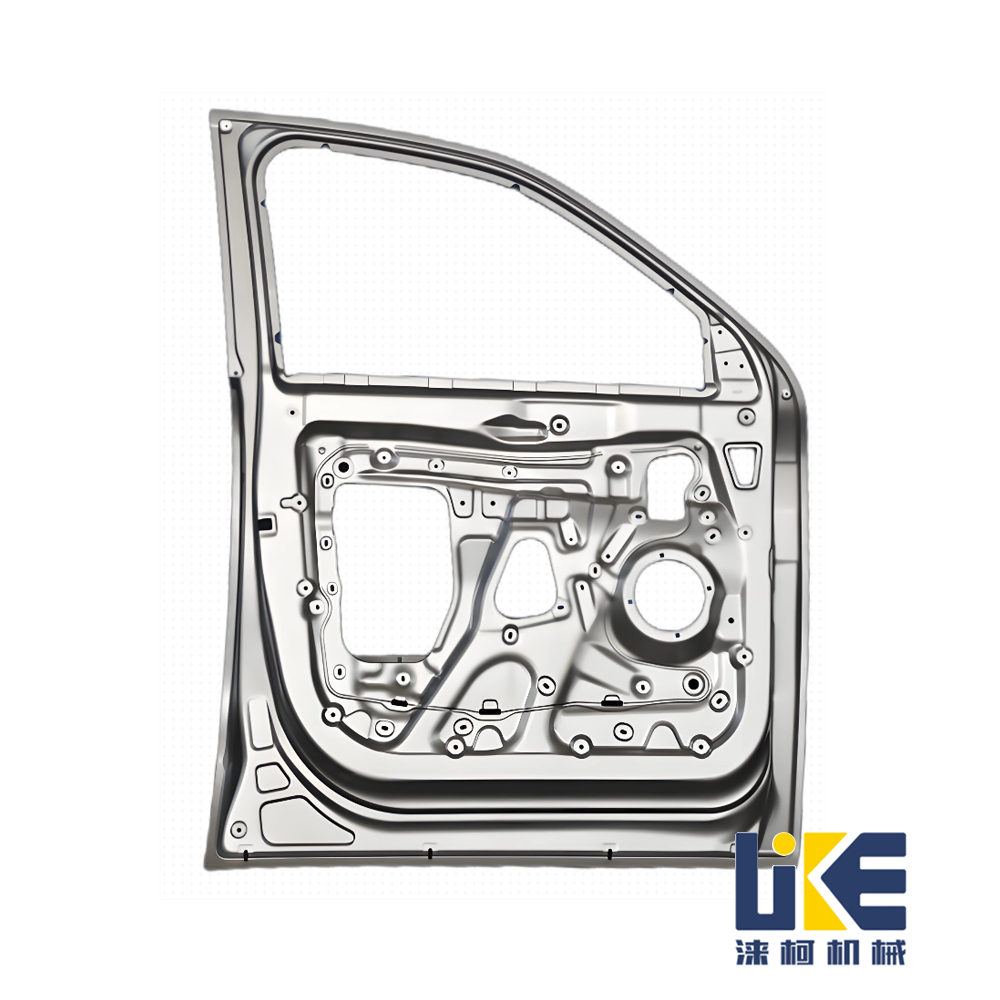

Automotive and metal stamping parts

Automotive and metal stamping parts