Tableware and metal stamping parts

Before industrial stamping, metal tableware such as silver spoons and copper pots were mainly forged by hand and had extremely high prices. The modern tableware industry, especially stainless steel knives, forks, spoons, pots, bowls, and pans, is the most typical and mature assembly line application scenario for metal stamping technology.

The following are the specific roles and application scenarios of metal stamping parts in the tableware industry:

1. Flatware: - Core Applications

This is the most widely used stamping process in tableware. The stainless steel spoons and forks we use in our daily lives are almost all directly stamped and formed from metal sheets (coils).

Spoons:

Forming/Deep Drawing: The head of the spoon is a concave bowl shape. This is formed by forcibly pressing down a flat steel plate through the stretching process of a stamping die.

Embossing: patterns on the handle of the spoon Logo, It's not engraved, but instantly pressed out with a mold under several tons of pressure.

Forks:

Blanking: How did the gap in the fork come about? It's like cutting cookies with a punch press, cutting off excess metal and leaving only fork teeth.

Bending: Forks usually have a slight curvature to facilitate scooping up food, which is also achieved through the stamping and bending process.

Stamped Knives:

Difference: This type of knife is usually thinner and lighter, commonly seen in steak or fruit knives. They are shaped like a knife directly punched out of a steel plate and then cut.

Comparison: Compared to expensive "forging knives" (made by burning thick steel blocks red), stamping knives have extremely low costs and are suitable for large-scale production.

2. Hollowware:

The manufacturing process of stainless steel bowls, plates, and insulated cup liners is a textbook level application of Deep Drawing in stamping technology.

Stainless steel bowl/basin:

Craftsmanship: Imagine placing a circular flat steel plate on a mold, and using a huge punch in the middle to push it down. The steel plate will be stretched and deepened like dough, and finally turn into a bowl.

Curling: The edge of the bowl mouth is usually rounded and does not cut hands. This is the final process of stamping, rolling the sharp edges into a circle.

Insulated cup liner:

Craftsmanship: An extremely deep cylinder. This usually requires multiple stretches (stretching a little at a time through stamping, dividing into several parts) to form such a deep shape without breaking.

3. Cookware Components

Although the body of high-end cookware may be die cast or integrally formed from multi-layer composite steel, its accessories cannot be separated from stamping.

Lids:

Both the stainless steel edging of the glass lid and the all metal lid are stamped parts.

Handle Brackets:

The metal seat that connects the pot body and the rubberwood handle is usually a stamped part spot welded to the pot body, which must be very sturdy and able to withstand the weight of a full pot of food.

Steam grid/filter:

Perforating: The densely packed holes on the steaming grid are quickly punched out by CNC punching machines.

4. Kitchen Gadgets

Graters:

Function: That metal plate covered in holes with sharp edges.

Process: This is a very special stamping process. The mold not only needs to punch holes, but also needs to lift the edges of the holes to form sharp cutting edges for cutting vegetables.

Bottle opener:

Bottle openers that utilize the principle of leverage are usually stamped from thick steel plates, with high hardness and no deformation.

5. Why can't the tableware industry do without stamping?

Hygiene:

Stamping parts are integrally formed without gaps. If welding is used, the weld seam is prone to accumulate dirt and bacteria. The surface of the stamped stainless steel bowl is smooth, easy to clean, and meets food safety standards.

Low Cost:

The stainless steel spoons in the supermarket cost a few yuan each, and only stamping technology can achieve this price. Once the mold is opened, it can be produced in one second, with high material utilization rate.

Consistency:

Restaurants require hundreds or thousands of identical plates and knives and forks for easy stacking and arrangement. Stamping ensures that the size and curvature of each product are exactly the same.

Surface decoration:

Through molds, mirror, frosted, or complex relief patterns can be made on metal surfaces to enhance the grade of tableware.

summary

In the tableware industry, the role of metal stamping parts is to turn cold steel plates into warm daily necessities.

It stretched the steel plate into a bowl;

It punched the steel plate into forks;

It embossed the steel plate into a beautiful spoon handle.

It is precisely because of mature stamping technology that stainless steel tableware can be so cheap and durable, replacing fragile porcelain and expensive silverware, and becoming the protagonist of modern dining tables.

Decorative items and metal stampings

Decorative items and metal stampings

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

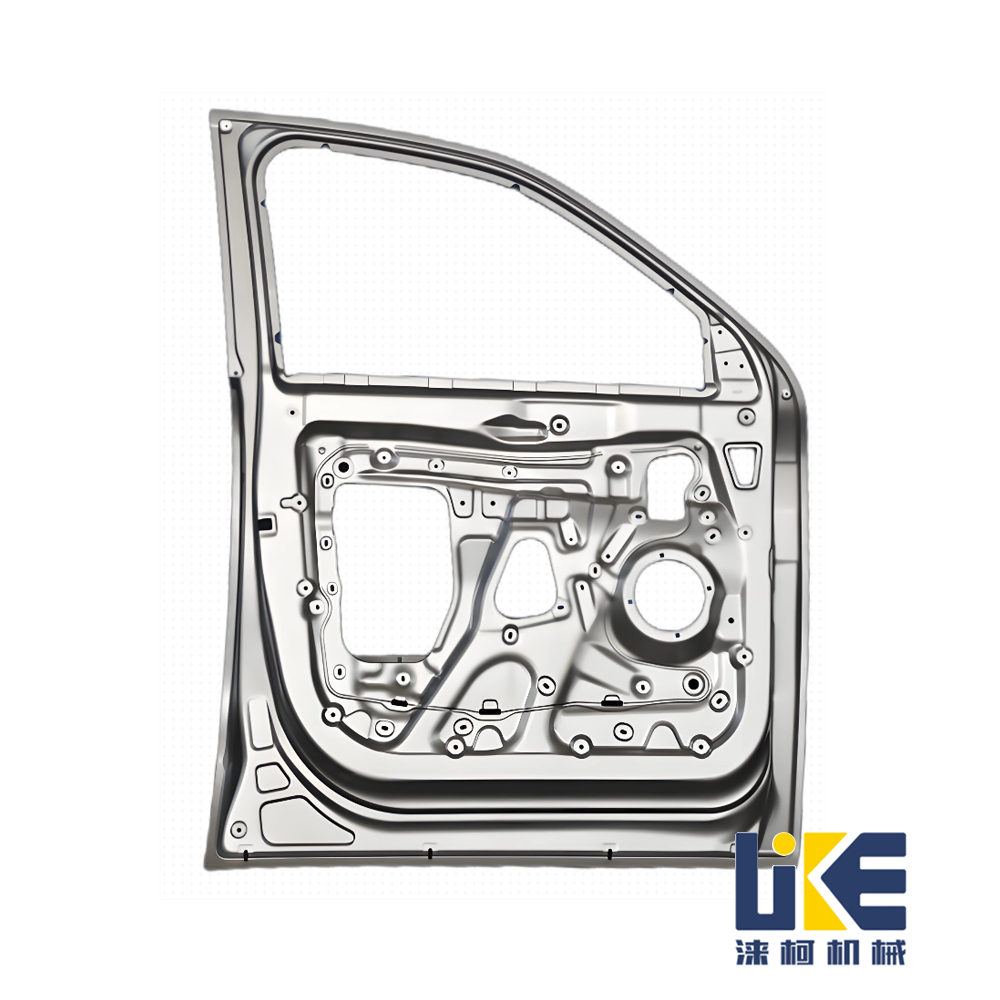

Automotive and metal stamping parts

Automotive and metal stamping parts