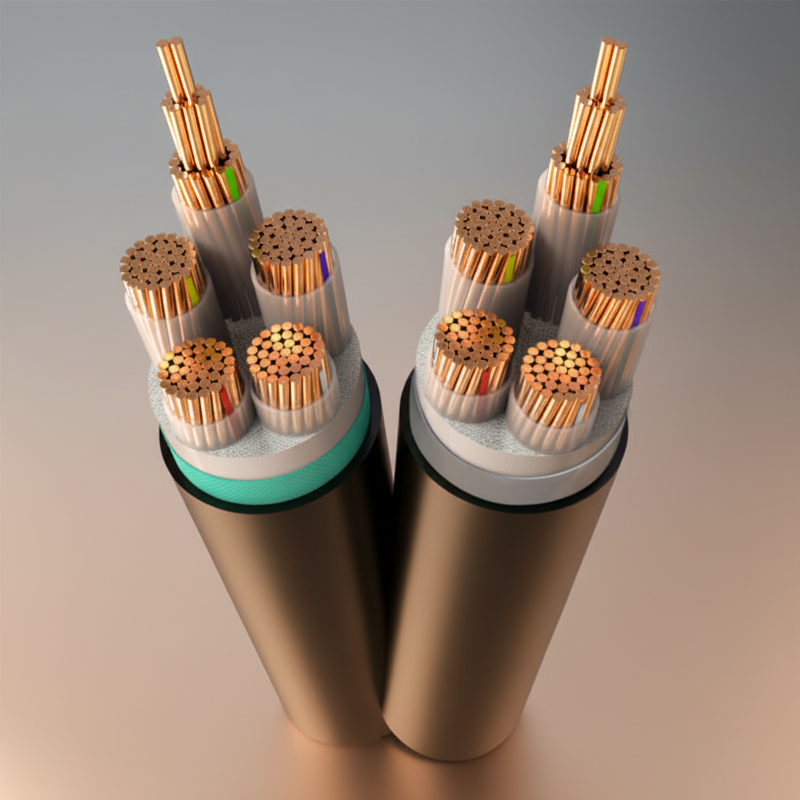

Cables and metal stamping parts

2. Cable Management - the "steward" of cables

Cables cannot be scattered randomly inside equipment or buildings, and need to be fixed with stamped parts.

Cable Clamps:

Function: Fix the wiring harness on the chassis wall or wall surface.

Process: Steel strip stamping and bending, usually used in conjunction with rubber gaskets to prevent cable wear.

Metal Cable Ties:

Function: Use stainless steel stamped zip ties to tie cables in ships, outdoors, or high-temperature environments (where plastic zip ties may age and break).

Process: Stainless steel strip stamping, with a special ball locking structure on the head.

Strain Relief:

Function: Installed at the entrance of the cable entering the casing, it clamps the cable to prevent external pulling from causing internal solder joints to break.

3. Shielding&Grounding - the "bodyguards" of signals

Anti interference is crucial for cables used for transmitting data, such as coaxial cables and signal lines.

Shielding Cans/Clips:

Function: To connect the cable to the PCB board, attach a metal stamped cover to prevent EMI leakage or intrusion.

Grounding Clips:

Function: Puncture the outer skin of the cable to contact the shielding layer, and introduce static electricity into the metal shrapnel on the ground.

Tinplate shell:

Many cable connectors have a stamped tin liner inside, specifically designed for shielding.

4. IDC - Insulation Displacement Contact

This is an efficient connection technology commonly found in Ribbon Cables.

IDC terminal:

Function: There is no need to peel off the insulation of the cable. The terminal has a stamping structure like a "knife edge", which directly punctures the insulation layer and contacts the copper core when pressed down.

Process: This type of terminal requires extremely high precision for the cutting edge of the stamping mold, and the insulation skin must be cut at once, but the copper wire cannot be cut.

5. Armoring

Although the metal layer of armored cables is usually wrapped, the related accessories are stamped.

Armor joint accessories: used to fix the locking plate and grounding ring of the armor steel strip.

Wire protection sleeve joint: a joint between a metal hose (used to protect cables) and equipment, with a locking claw usually made of stamped parts.

Why can't the cable industry do without stamping?

Processing of conductive materials: Cable connectors must be made of copper (with good conductivity) or copper alloy (with elasticity). These materials have good ductility and are very suitable for stamping processing, but not suitable for cutting (copper is too soft, cutting is easy to stick to the knife and wastes materials).

Massive production: The number of terminals consumed globally each year is in the trillions. Only high-speed stamping molds (hundreds to thousands of times per minute) can meet this astronomical demand for production capacity.

Elastic contact: The reason why plugs and sockets can make close contact is due to the elasticity of metal. The stamping process combined with high-performance copper alloy can produce contact springs with perfect rebound force.

summary

In the cable industry, metal stamping parts are the "nodes".

The cable itself is the "road", while the stamped parts are the "toll station" (connector), "guardrail" (fixing clip), and "terminal station" (terminal) on the road. Without stamped parts, cables cannot complete the final delivery of electrical energy and signals.

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

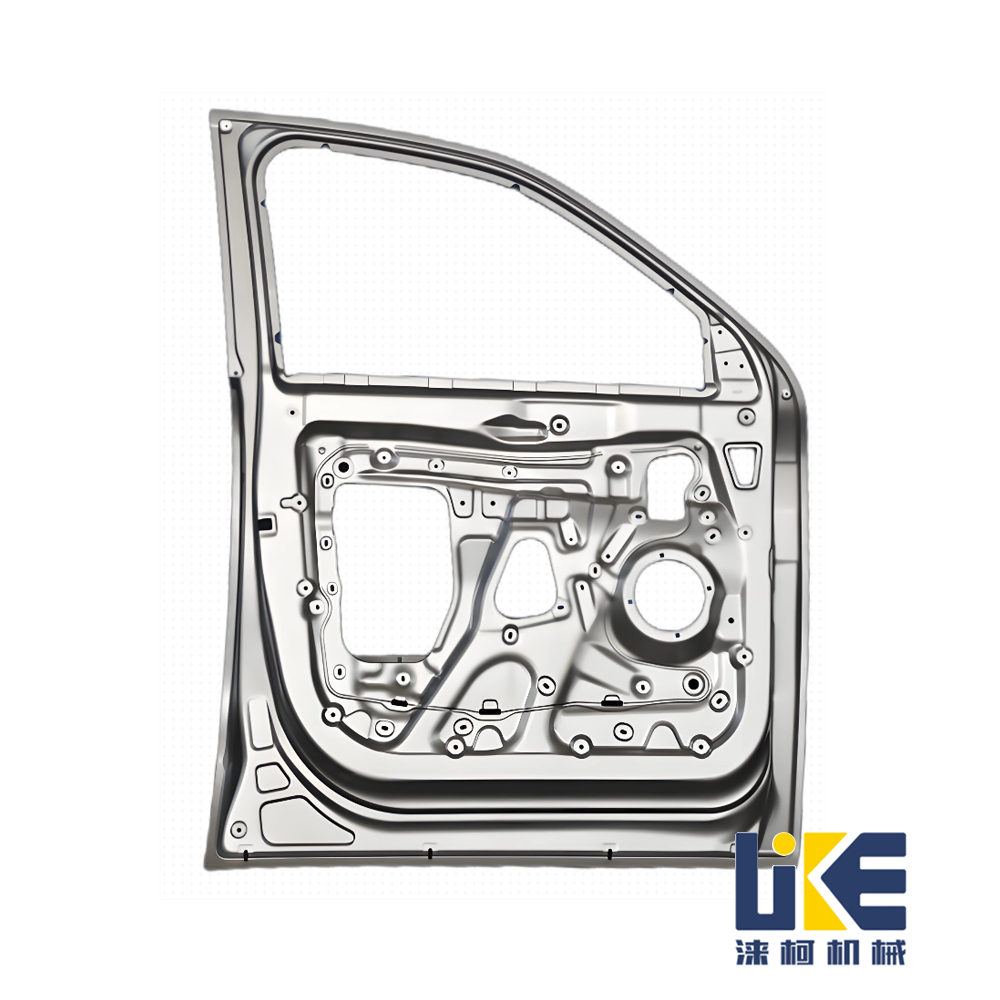

Automotive and metal stamping parts

Automotive and metal stamping parts

Cables and metal stamping parts

Cables and metal stamping parts

Numerical control equipment and metal stamping parts

Numerical control equipment and metal stamping parts